|

FinescrollsawHegner scroll saw review |

|

|

Hegner scroll saws are well known for their quality. In this review I share with you my impressions on the model Multicut 2S with variable speed. |

|

The sturdy body of the Hegner Multicut 2S is made of cast iron. It stands firmly almost anywhere. With standard motor speeds no vibrations are felt, for very high speeds you simply fix the saw to a table. Its 46 cm of goose neck (18 inches) provide ample space even for pieces far beyond the usual sizes. Blade tension is set with an easy to reach knob located in the rear of the arm. |

|

The first impression you get is that

this scroll saw is designed with quality in mind, every part looks

good and strong.

A vacuum cleaner can be fit into a especially designed tube to take away most of the saw dust. |

|

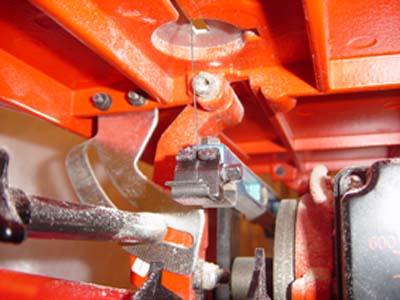

The Hegner scroll saw uses blade clamps on the bottom blade end, which permits easy interchanging and replacement of blades. |

|

Mounting the blade on the clamp is an easy operation with the help of a small cavity with the exact size of the clamp. You simply hold the blade in position and tight the blade holder with the provided tool. |

|

The blade is then encased in position below the cutting table. |

|

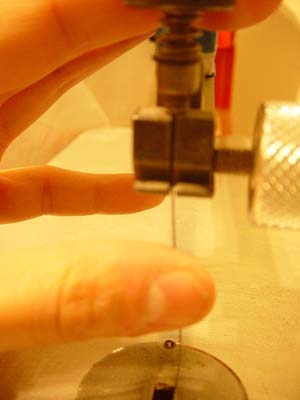

The upper part of the blade is held by the quicklock tension release system (not in all Hegner models). Making a large number of inner cuts is very easy, the upper blade end can be mounted, tensioned and released once and again without effort: |

|

You simply insert the blade in the blade holder slot, |

|

hold it by tightening the wheel, |

|

and you reset the tension by pushing forward

the red handle. To release the blade you do the same in

reverse order. This process can be repeated many times and becomes

very effective and automatic. Cutting quality can be described with just one word: excellent, even with thick and hard woods.

|

|

This model has a variable speed control, between 400 and 1400 revolutions. I have never used more than 1000. |

|

The table can be tilted to a maximum of 45 degrees. |

|

The tilting degree

is controlled precisely by a graduated ruler. This was my first scroll saw and I am convinced I will never need another one, at most replace parts of course. When I was hesitating which scroll saw to buy Mike Moorlach recommended me to buy this one. Now I know he was very right and I am grateful for his valuable advice. Sitting in front of this machine and turning it on is always a nice experience. |

|

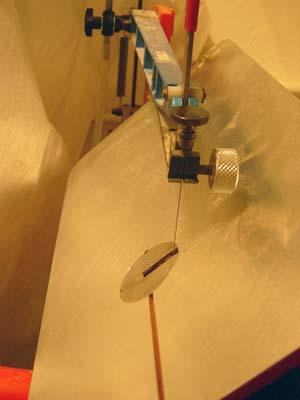

This picture is courtesy of Tom Cocks from the United States. It shows the table he has specifically designed for the Hegner scroll saw. Tom Cocks is a member of the Carolina Scrollers Scroll saw club. |

|

Mike has sent me a few Flying Dutchman scroll reverse saw blades for review. I had never tried these ones. |

|

They have the particularity that they have upward and downward teeth. This design produces remarkably clear cuts, without fuzz on the bottom of the wood. Standard blades with all teeth downwards leave lots of fuzz on the bottom of the wood. The picture on the right is the bottom of 1/2 inch plywood. The right side has been cut with a high quality but standard blade, and a lot of fuzz is visible. The left side is cut with one of Mike's blades. The cut is remarkably clear, no sanding is necessary. This can be very practical with projects that involve many inner and small cuts. These blades are a discovery for me and I very much recommend them. If you live in U.S.A. they are for sure your best option. They are called the FD-SR blades. |

|

|

© Copyright 2024 Pedro López Rodríguez. All rights reserved. |