|

FinescrollsawFrequently asked questions |

|

| This page addresses the most frequently asked questions I receive about scroll saws and my patterns. The answers provided are intended as a helpful starting point for beginners and are not exhaustive. As you gain more experience, I encourage you to explore further. |

How can I buy the patterns in this website?You should write to me at [email protected], indicating where you are from and the numeric codes of the designs you wish to order. I will reply with all the necessary information. |

I have sent several emails and have not received a response. What is the reason?I respond to all emails without exception, typically two or three times a day. You should almost always receive a reply within a few hours. If you haven’t heard from me, it's likely that my email was directed to your spam folder. |

How long will my order take to arrive? Where can I track my order?All orders are shipped via registered mail. I typically ship orders the day after receiving payment. After shippsing your order I will send you the tracking number. Within Europe, deliveries usually take about seven business days. For the USA, Canada, and Australia, shipping generally takes around ten business days. However, delays can occur, especially during peak seasons such as summer and Christmas. Delays to the USA are often caused by parcels waiting for customs clearance. On rare occasions, delivery may take longer than expected. If your order has not arrived after twenty business days, please contact me, and I will send a replacement at no extra cost to you. Please note that lost parcels are very rare. You can track your shipment on your local postal service's website. |

What is the quality of your patterns?I create my patterns using the most advanced graphic design techniques available today. The computer works with incredible precision, ensuring that all project pieces fit together perfectly. With careful work on your part using the scroll saw, you won't need to adjust, adapt, or sand your pieces to make them fit. I initially started making scroll saw patterns for my own enjoyment, as I was dissatisfied with the ones I had found. Once I finish a pattern, I create a three-dimensional virtual model of the project and assemble it digitally, just like I would in real life. This allows me to identify and correct any issues before finalizing the design. Afterward, I lay out the pattern with all the necessary details and print it out. I use A3 and A4 printers for this, not photocopies. I'm confident that my patterns are the most technically accurate available. |

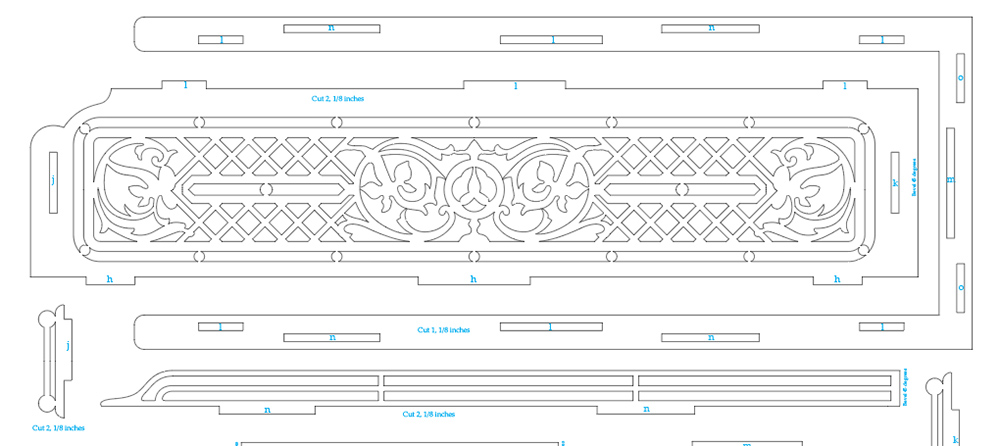

How do the patterns look like? Can I see some samples?Yes, here you can see a samples of my patterns. Clear lines, perfect symmetries and angles and many indications with letters and numbers to show the position of pieces. Some overlay pieces are shown in position with dotted blue lines. |

| In the page of patterns for sale you can download a pattern of a fruit basket in PDF format. |

I have seen some of your patterns for sale in different websites, where should I buy?What you’ve seen on other websites is not my patterns. What you’ve come across are variations of the same design. Some of these designs, both on my website and others, are classical patterns that are often between 100 and 140 years old. Since these designs are in the public domain, anyone can create and sell edited versions. The patterns you see on other websites may look similar, but they can differ significantly. Some sellers simply offer photocopies or basic adaptations of the original designs, often with their logo or trademark added. Others may provide high-quality versions, but in my case, I fully restore these classical designs. I create new, clean patterns using advanced vector graphics software, ensuring perfect symmetries, slots, tab holes, straight lines, circumferences, and more. I only sell my patterns through this website—nowhere else—and I do not sell anyone else's patterns. As for the question of where to buy, I encourage you to choose what you think is best for your needs. If you're unsure whether my pattern is superior to others, feel free to ask different sellers any questions you may have. If you'd like, I can also send you a sample of the pattern you’re interested in via email, so you can see its quality firsthand. |

Can I use any wood thickness with your patterns?This is by far the most common question I receive. Patterns are typically designed for a specific wood thickness, such as 1/8" and 1/4" wood, or 3 mm and 6 mm wood. Once a pattern is designed, it can be scaled to any size as needed. However, the wood thickness must also be scaled in the same proportion. For example, if a pattern is designed for 4 mm wood, and you want to use 1/8" (approximately 3.175 mm) wood, you can easily calculate the scale factor. Dividing the thickness of the desired wood (3.175 mm) by the thickness of the pattern wood (4 mm) gives us 0.79375, which we round to 0.80. This means that the pattern should be scaled to 80% of its original size to match the 1/8" wood thickness. With this scaling, everything will fit properly, and the final model will be 80% the size of the original. This scaling process is accounted for during the design phase, so the final size should work well. Any good copy shop should be able to scale your pattern to the desired size for the project. |

Why do you have two versions of the pattern for the Eiffel tower and not for the rest?The first version of the pattern was designed for 3 mm, 4 mm, or 1/8-inch wood. However, someone suggested that this thickness might be too thin for the tower's sides, and that a thicker wood would be better. While this is just an opinion, I decided to create a second version of the pattern with the same height, but using double the thickness for the sides of the tower. This second version is the one referenced on the order page. If you have a specific height in mind for your Eiffel Tower, let me know, and I will help you find the best pattern and scale to meet your preferences. |

What kind of copyright limitations do I have if I buy one of your patterns? Can I sell the finished projects?The pattern is for your personal, exclusive use. You are not allowed to sell, rent, distribute, or share copies of the pattern with anyone, under any circumstances. You may make as many copies as needed for your personal use in creating projects, but these copies are subject to the same limitations as the original pattern. You are free to make as many projects as you wish from the pattern, and you may sell the finished projects without restriction. |

Do you sell digital versions of the patterns, in pdf, dxf or other formats?Generally, we only send printed patterns via regular mail or any courier service of your choice. When I first started selling the patterns, I sent some as PDF files by email (8 or 10 sheets), but that quickly led to problems. Some of the pattern pages need to be printed on A3 paper. I received numerous questions about printers, configuration issues, paper sizes, software compatibility, and where to print A3 sheets. Printing costs at some shops were also a concern, as the service can be expensive in some areas. Others even asked how to print A3 sheets across two separate A4 pages and then join them. Because of the time-consuming nature of addressing these complicated issues individually, I decided to stop offering patterns in digital format and now only provide them in printed form. However, if you're confident you can handle any printing issues, feel free to contact me at [email protected]. If you plan to use the digital files with a laser cutter, please note that most of my models require bevelled cuts. Standard laser cutters cannot produce beveled edges, so you’ll need to either add the bevels after cutting or modify the pattern to suit your needs. Unfortunately, I won't be able to assist with these modifications. |

¿Where can I buy clock inserts or mechanisms?If you are located in Europe I recommend you http://www.selva.de They have a large collection of all types of clock inserts, mechanisms, chimes, etc, in different sizes and forms. You can also visit Hobbies (www.alwayshobbies.com). They supply customers from the UK and worldwide with scroll saws, blades, clock insert, movements and more. In Spain you can buy some at http://www.ruizrevuelto.com. In the USA there are many shops selling clock inserts and clock mechanisms, for example www.klockit.com, www.klockworks.com and many others (if you want me to include a shop here simply write me). |

Which scroll saw is best? What should I take into account to choose one?The essential condition for a scroll saw is that it can use pinless blades. |

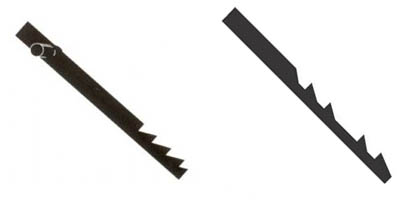

On the left is a pinned blade, and on the right is a pinless blade. Pinned blades are useful but not ideal for fretwork involving small inner cuts. This is because inner cuts require a pilot hole to thread the blade through. For pinned blades, the pilot hole needs to be larger to accommodate the pins, making fine or intricate inner cuts difficult or even impossible. Pinless blades, requiring smaller pilot holes, are much better suited for detailed fretwork.

On the left is a pinned blade, and on the right is a pinless blade. Pinned blades are useful but not ideal for fretwork involving small inner cuts. This is because inner cuts require a pilot hole to thread the blade through. For pinned blades, the pilot hole needs to be larger to accommodate the pins, making fine or intricate inner cuts difficult or even impossible. Pinless blades, requiring smaller pilot holes, are much better suited for detailed fretwork.

|

| Holding a pinned blade is easier than a pinless one, making scroll saws that only accept pinned blades simpler in design and generally more affordable. While adapters are available to use pinless blades on these saws, they can be tricky to install and may cause issues depending on the saw. If you want to avoid these hassles, it's best to invest in a scroll saw designed for pinless blades. However, if you have a pinned-blade-only saw, you can still handle most inner cuts. For very fine or small inner cuts, you can always switch to a hand saw for precision. |

| Equally important as using pinless blades is the ability to quickly release or tighten the upper blade clamp and adjust blade tension, making inner cuts more efficient. While it's convenient, though not essential, to avoid using external tools for this, the system varies by scroll saw quality. For example, my Hegner Multicut 2S has a 'Quick Clamp' system that is both practical and efficient. Other high-end scroll saws offer similar features. |

Which scroll saw blades do you recommend? ¿Do I need any other tool?Scroll saw blades can be classified in flat and spiral, and for each of these there are some different types. For beginners I recommend standard flat blades, of low size, when you are more experienced you can explore the uses of other types of blades. If you live in the USA an excellent choice is Flying Dutchman blades. To begin with you do not need any other electric tool, however a small drill press is very useful to make the pilot holes for the inner cuts quickly. The drill press I own is the Dremel 200 multifunction, with its vertical support, which is sold separately. |

What is the best wood for your projects? Can I use mdf?Choosing the right wood depends on your project, and hardwood is often the best option. While it is more expensive than plywood, hardwood offers unmatched beauty and versatility, with each type having unique colors, grains, and levels of hardness that enhance the appearance and durability of your work. Mixing two or three types of hardwood can add subtle color variations that make your project stand out. However, hardwood typically comes in smaller widths, around 15 to 20 cm depending on the type. If your project requires larger pieces, you’ll need to edge-glue multiple boards together. This process requires the right tools and some skill but is worth considering for larger designs. As you become more serious about scroll sawing, you’ll find yourself using hardwood for most of your projects, as it truly brings out the craft's potential. Below, we explore the eight most common hardwoods used in scroll sawing, discussing their colors, grains, hardness, and typical board widths. Oak is a durable and widely used hardwood known for its prominent grain patterns. It comes in two main types: red oak and white oak. Red oak has a warm reddish-brown hue with a coarse, straight grain, while white oak is lighter, with a golden tan to pale brown shade and tighter grain. Oak is moderately hard (1,200–1,400 Janka rating) and is available in board widths ranging from 6 to 12 inches, making it suitable for large or intricate scroll saw designs. Walnut is prized for its rich, dark brown color with purplish undertones and a straight, fine grain that gives it an elegant appearance. It is moderately hard (around 1,010 on the Janka scale), making it easy to work with while retaining durability. Walnut boards typically range from 4 to 10 inches in width and are ideal for projects where a sophisticated, polished look is desired. Maple is a versatile hardwood with a creamy white to light golden tone and subtle grain patterns. Hard maple is one of the hardest woods (1,450 Janka), offering excellent durability for fine details, while soft maple is more forgiving and easier to cut. Maple boards are commonly available in widths of 6 to 12 inches and are often used for contrasting designs or intricate patterns. Cherry wood is renowned for its warm, reddish-brown tone that deepens with age and exposure to light. It has a smooth, fine grain that lends itself beautifully to detailed scroll saw work. Cherry is moderately hard (around 950 on the Janka scale), making it easy to cut and sand. Boards are often found in widths of 6 to 10 inches, ideal for decorative panels and layered designs. Mahogany features a deep reddish-brown color and straight, consistent grain that exudes a classic look. It is moderately hard (800–900 Janka) and works smoothly with scroll saws, making it a favorite for furniture accents and intricate decorative pieces. Mahogany boards are typically available in widths of 6 to 12 inches. Birch has a light, creamy yellow tone with subtle straight grain, making it an excellent choice for projects requiring a clean and simple look. It is relatively hard (1,260 Janka) and easy to cut with a scroll saw, though its hardness may require sharp blades for intricate patterns. Birch boards are commonly found in widths of 6 to 10 inches. Ash is a durable hardwood with a pale blonde to light brown color and a coarse, straight grain. It resembles oak but is lighter and slightly less hard (around 1,200 Janka). Ash is often used for larger scroll saw projects due to its availability in wide boards, ranging from 8 to 12 inches, and its excellent workability. Padauk is a striking hardwood known for its vivid orange to reddish-brown color, which darkens over time. It has a coarse, interlocked grain and is moderately hard (around 1,725 Janka), offering both durability and unique aesthetics. Padauk boards are typically available in widths of 4 to 8 inches and are ideal for creating bold, eye-catching scroll saw designs. Each hardwood offers distinct advantages for scroll sawing, from the rich warmth of cherry and walnut to the bold color of padauk and the versatility of maple. Choosing the right hardwood depends on the project’s requirements, including color, grain, and durability. With boards available in various widths, from 4 to 12 inches, these hardwoods provide the foundation for creating stunning, intricate scroll saw projects that highlight the natural beauty of wood. Since the widths of hardwood boards are often limited, you may frequently need to edge-glue two or even three boards together to achieve the desired size for your project. While this may seem complicated at first, it is a straightforward process with the right tools and technique. The primary tool required for this task is a set of bar clamps or pipe clamps, which are used to hold the boards tightly together while the glue sets. Additionally, a jointer or a hand plane is essential to ensure the edges of the boards are perfectly straight and smooth for a tight, seamless bond. Here is a step-by-step guide to edge-gluing hardwood boards: Prepare the Edges: Start by inspecting the edges of the boards to ensure they are straight and square. If they are not, use a jointer or a hand plane to smooth and straighten the edges. Clean, smooth edges are critical for a strong and seamless bond. Dry Fit the Boards: Arrange the boards side by side to check the alignment and grain matching. This step ensures the boards fit together snugly and the grain flows naturally for aesthetic appeal. Apply the Glue: Apply a thin, even layer of wood glue (such as Titebond) along one edge of each joint. Use a brush or your finger to spread the glue evenly. Clamp the Boards: Align the boards and position them in bar clamps or pipe clamps. Place clamps alternately above and below the boards to prevent bowing. Tighten the clamps gradually, ensuring even pressure across the entire joint. Excess glue should squeeze out along the seams. Check for Alignment: Before the glue sets, double-check that the boards are aligned and flat. Use a straightedge or a level to ensure the surface remains even. Remove Excess Glue: Use a damp cloth to wipe away any excess glue along the joints. This step prevents hardened glue from interfering with sanding or finishing later. Allow the Glue to Cure: Leave the boards clamped for several hours or as recommended by the glue manufacturer. For best results, allow the joint to cure overnight. Finish the Surface: Once the glue has dried, remove the clamps and sand the surface to achieve a smooth, even finish. Use a belt sander or orbital sander for larger projects. By following this procedure, you can successfully edge-glue hardwood boards to create larger panels for your scroll saw projects. With practice, this process becomes an essential skill for crafting high-quality, professional-looking pieces. Plywood is more versatile for larger projects since it comes in bigger sheets. There are different types, and you’ll want to choose a sturdy one—the harder, the better. Be cautious with cheaper plywoods, especially those with a low-quality side, as they aren’t great for scroll saw work. Baltic birch plywood is a solid, reliable option. As for MDF, I’m not a big fan for scroll saw projects. It’s made with glue and other materials that can heat up and gum up the blade, causing cutting issues. That said, some people don’t seem to have this problem, so it might be worth experimenting to see if it works for you. |

I have bought a scroll saw and I am very disappointed, my cuts are disastrous, a total mess, I think this is not for me.To get comfortable with an electric scroll saw, I recommend two 20-minute sessions a day. That’s it! Grab some inexpensive wood and practice cutting simple shapes—rectangles, circles, whatever—and start scrolling. At first, it’ll probably be messy. You might miss the lines, and the cuts could look rough, but don’t worry! That’s totally normal when you're just starting out. Stick with it for a few days, and you'll start getting a feel for it. It’s a lot like learning to drive. At first, steering feels awkward, but after a few days, it becomes second nature. Once you’re following the lines fairly well, try a simple project. It won’t be perfect, and that’s okay—the experience is what matters. Practice your finishing skills, too—get familiar with varnishes and other techniques. It's better to experiment on practice projects than risk ruining a big one later. The key is to accept that struggling in the beginning is part of the learning process. Keep at it, and you’ll see real progress over time! I’d like to share a problem I experienced and that others have mentioned regarding the Hegner scroll saw and similar models. When you first start using the saw, the blade often slips out of the upper clamp when tensioning. In my case, I couldn’t tighten the blade at all—it would slip out immediately, no matter how much or little tension I applied. The clamp’s inability to hold the blade was so frustrating that I thought there was a defect. Fortunately, my friend Mike Moorlach from the U.S. explained the cause and provided a solution. The issue is simple: blades are slightly coated with oil from the factory to prevent corrosion, and sometimes the clamps are also greasy. This oil causes the blade to slip, making it impossible to secure. The fix is just as simple: clean the blade’s end and the clamp with solvent and a small piece of cotton. Once done, the problem disappears completely. |

|

© Copyright 2024 Pedro López Rodríguez. All rights reserved. |